Applications >HOME >Applications List

High-resolution measurement of angles and positions using an absolute encoder

There is an increasing demand for high-resolution angle and position measurement using absolute encoders.

Combined with the CNT-49 series (custom-made: ASL specifications), measurements can be made easily and precisely.

- Zero-setting is troublesome every time the power is turned on again.

- To avoid counting errors when the measurement target moves at high speed.

- To measure rotation and position with high accuracy and high resolution.

- Want to know the absolute angle to the origin, not the relative angle.

Servo motors, etc. |

|

←

|

|

→ |

|

|

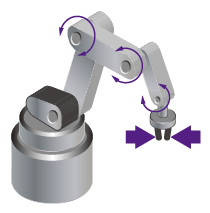

Industrial Robots

Angle Measurement of Joints Tool position measurement |

|

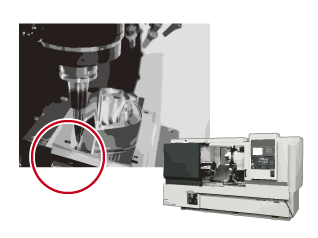

Machine Tools

Tool position measurement Workpiece position measurement |

|

Automation equipment

Conveyor equipment Picking device |

|

Elevator

Accurately detects the elevation position |

|

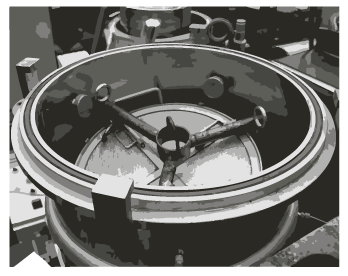

Semiconductor manufacturing equipment

Precisely measures and controls the position of wafers |

|

Aircraft

Measure flap and wing angles |

|

Cameras and other optical equipment Precise measurement of lens position |

|

Automobiles

Measuring steering angles |

Why Choose Us?: Features of Absolute Encoders and Meters

Absolute encoder- High accuracy:

High-precision measurement and positioning. No counting errors even when the measuring object moves at high speed,

making them suitable for high-precision systems.

- The position at power-on is immediately known:

Absolute position information is immediately available when power is turned off and on again.

- No need to return to the origin:

No need to return to the origin each time, leading to improved work efficiency.

- Support for multiple rotations:

Multiple rotations can be detected, allowing measurement of a wide range of angles.

- Compact size:

Compact: Multiple slits can be placed on a single code wheel, making it compact even with high accuracy.

Measuring instrument (custom made for CNT-49 series)

- RS-232C output:

Continuous data output is possible.

- RS-422 serial communication (input):

Supports SSI communication 12bit - 22bit. Digital communication is resistant to transmission noise.

- 16bit analog output with 0.5ms update:

Measurement data can be checked with your oscilloscope, etc.

- Factory setting of measuring instruments and creation of setting value table are also available.

| Base model | Points | Overviews | |

|---|---|---|---|

|

CNT-4921/4931 Pulse integration (reversible) counter Product page |

RS-232C RS-485 Analog output Alarm output BCD output LINKSHIP Compatible |

- 16-bit analog output with 0.5ms update - Various options such as RS-232C/RS-485/BCD output - Up to 4 alarm outputs can be mounted - Power supply for sensor 12V (standard)/5V (optional) - 46x98 size panel meter with scaling function |

|

CNT-4922 Pulse integration (reversible) counter Product page |

RS-232C RS-485 Analog output Alarm output BCD output LINKSHIP Compatible |

- 16-bit analog output with 0.5ms update - Various options such as RS-232C/RS-485/BCD output - Up to 4 alarm outputs can be mounted - Power supply for sensor 12V (standard)/5V (optional) - 46x98 size panel meter with scaling function |

Customization:We support from one unit. >Customization page

| Boxed - Calibration is possible as an embedded product. - Calibration documents and traceability charts can be issued. |

Function change - Input, output, calculation, etc. - Changing the input power supply or sensor power supply output - Adding arithmetic formulas - Adapting output voltage values, communication specifications, etc. |

|

Please consult with us about your desired boxed or rack assembly.

|

PC

PC Loggers

Loggers Oscilloscopes, etc.

Oscilloscopes, etc.