Capacity Type Volumetric Flow Sensor XFS Series

| Compact, Lightweight, Highly accurate, and Compatible with a wide variety of liquids |

Widely used for general measurement and control of liquids in the industrial field and for fuel consumption meters for automobiles.

| Compact and lightweight | The entire sensor is designed to be compact and lightweight. |

| For a wide variety of liquids | The volumetric design minimizes the influence of liquid viscosity on accuracy, making the sensor suitable for a wide variety of liquids. |

| High accuracy and High resolution |

The special elliptical gear minimizes pressure loss, enabling high accuracy measurement from very low to high flow rates. Wide measurement range and high resolution with optical sensor. |

| Backflow compensation | Forward / back flow pulse detection circuits allow accurate net flow measurement even in the presence of back flow. *With reverse flow compensation function is XFS-1205, 2205, and 1234. |

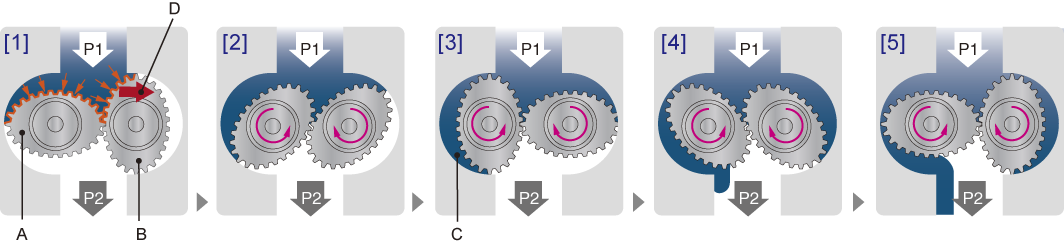

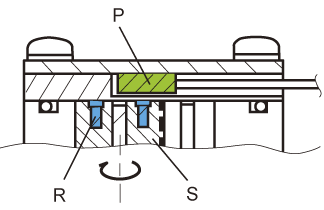

When fluid flows into metering chamber C from the direction of the arrow, a pressure difference (P1-P2) is generated between the inlet and discharge sides.

This pressure is applied to elliptical gears A and B, causing the gears to rotate (D), and a fixed amount of fluid is discharged in one rotation.

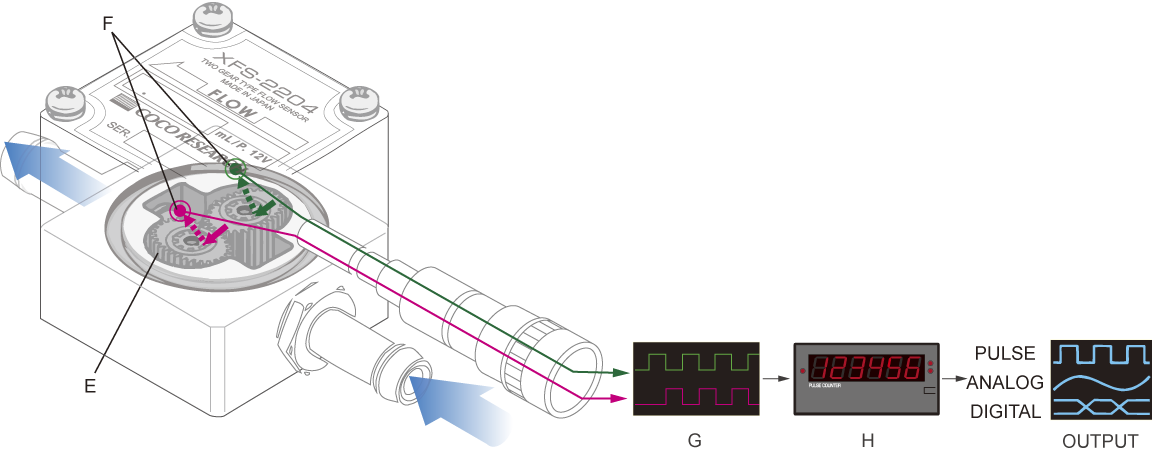

When the fluid passes through the measuring chamber E, the pressure causes the gears and the reflector to rotate in synchronization.

The reflection of light on the reflector is converted into voltage pulses by the optical sensor F and rotation detector G and output.

The pulse signals output from the sensors are input to a counter or other device and converted into various signals.

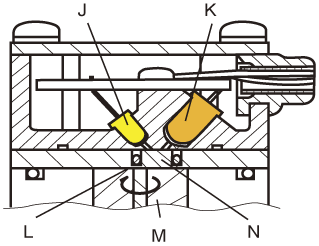

Two types of detection methods

| Optical type Gear rotation is detected by a reflector and optical sensor. High resolution enables highly accurate measurement of minute flow rates (e.g., engine fuel consumption measurement). |

|

Magnetic type Magnets are embedded in the gear and detected by a Hall IC installed on the rotation path. Effective for measuring fluids with poor light transmission (inks, mold release agents, paints, etc.). |

|

| Flowmeter Models Selection |

|

| Q1. What is the fluid to be measured? | |||||||||||

| Oil-based fluid ↓ SUS specification or ADC specification |

Water-based (corrosion-resistant) fluid ↓ SUS specification |

||||||||||

| Q2. How transparent is the fluid? | |||||||||||

| High transparency ↓ Optical or magnetic |

Low transparency (colored) ↓ Magnetic |

High transparency ↓ Optical or magnetic |

Low transparency (colored) ↓ Magnetic |

||||||||

| Q3. What is the maximum flow rate? | |||||||||||

| 120L/h or less ↓ |

300L/h or less ↓ |

120L/h or less ↓ |

300L/h or less ↓ |

120L/h or less ↓ |

300L/h or less ↓ |

120L/h or less ↓ |

300L/h or less ↓ |

||||

| Q4. Is backflow compensation required? | ↓ | ↓ | Q4. Is backflow compensation required? | ↓ | ↓ | ||||||

| YES ↓ |

NO ↓ |

YES ↓ |

NO ↓ |

↓ | ↓ | YES ↓ |

NO ↓ |

YES ↓ |

NO ↓ |

↓ | ↓ |

| XFS-1205 XFS-1234 |

XFS-1201 XFS-1204 XFS-1201M XFS-1204M |

XFS-2205 | XFS-2201 XFS-2204 XFS-2201M XFS-2204M |

XFS-1201M XFS-1204M |

XFS-2201M XFS-2204M |

XFS-1234 | XFS-1204 XFS-1204M |

- | XFS-2204 XFS-2204M |

XFS-1204M | XFS-2204M |

Specifications

| Model | XFS- 1201 |

XFS- 1201M |

XFS- 1205 |

XFS- 2201 |

XFS- 2201M |

XFS- 2205 |

XFS- 1204 |

XFS- 1204M |

XFS- 1234 |

XFS- 2204 |

XFS- 2204M |

|

| Measuring Fluid | [A] Oil-based | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| [B] Water-based, Corrosion Resistant | Standard | Standard | Standard | Standard | Standard | |||||||

| [C] Colored | Standard | Standard | Standard | Standard | ||||||||

| [A] Oil-based:Gasoline, kerosene, diesel oil, heavy oil, turbine oil, transmission oil, lubricating oil, etc.

[B] Water-based (corrosion resistant):Water, alcohol, chemical solution, etc. [C] Colored:Low transparency fluid, etc. Hydrogen peroxide, methyl ethyl ketone, caustic soda (NaOH), etc. cannot be measured. |

||||||||||||

| Rotational Detection | Optical | Standard | Standard | Standard | Standard | |||||||

| Optical + backflow compensation | Standard | Standard | Standard | |||||||||

| Magnetic | Standard | Standard | Standard | Standard | ||||||||

| Fitting | Hose fitting φ8 | Standard | ||||||||||

| Other options | [Each option] R1/8, R1/4, R3/8, Rp1/8, Rp1/4, Rp3/8 | |||||||||||

| Measurement accuracy | ±1.0%RD | |||||||||||

| Flow range | Measurement accuracy ±1.0%RD | 0.6 to 120L/h | 2.0 to 300L/h | 0.6 to 120L/h | 2.0 to 300L/h | |||||||

| Nominal pulse rate [mL/P.] | 0.1250 | 0.5000 | 0.03125 | 0.2500 | 1.0000 | 0.06250 | 0.1250 | 0.5000 | 0.03125 | 0.2500 | 1.0000 | |

| Max. working pressure | 2MPa | |||||||||||

| Operating temperature ℃[℉] | −10 to +60℃[-14 to 140℉] | −10 to +120℃[-14 to 248℉] | −10 to +60℃ [-14 to 140℉] |

−10 to +120℃[-14 to 248℉] | −10 to +60℃ [-14 to 140℉] |

−10 to +120℃[-14 to 248℉] | −10 to +60℃ [-14 to 140℉] |

−10 to +120℃[-14 to 248℉] | ||||

| Storage temperature ℃[℉] | −40 to +80℃ [-40 to 176℉] | |||||||||||

| Pressure loss [kPa] / at flow rate in ( ) | 2(45L/h) | 6(120L/h) | 2(45L/h) | 6(120L/h) | ||||||||

| Power supply | DC12V (9 to 15V) | |||||||||||

| Output signal | Voltage pulse (L=0V H=12V) | |||||||||||

| Connector | 5P. metal connector | |||||||||||

| Main material | Housing | ADC-12 | SUS316 | |||||||||

| Gear | Special carbon | |||||||||||

| Shaft | SUJ-2 | Ceramic | ||||||||||

| O-ring | FKM | |||||||||||

| Reflector | SUS316 | - | SUS316 | SUS316 | - | SUS316 | SUS316 | - | SUS316 | SUS316 | - | |

| Appearance | XFS-1201 |

XFS-1205 |

XFS-2201 |

XFS-2205 |

XFS-1204 |

XFS-1234 |

XFS-2204 |

|

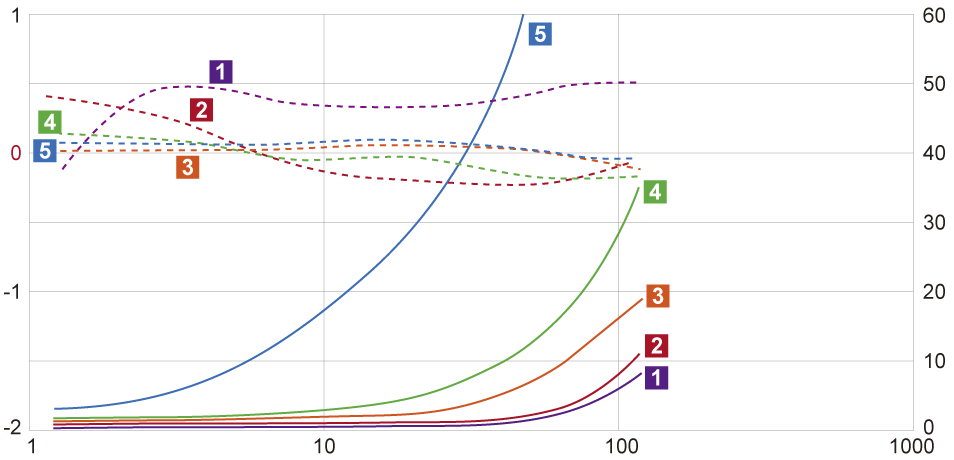

| Instrumental Difference [%] |

|

Pressure drop [kPa] |

[Dotted line]: Flowmeter performance curve [Solid line]: Pressure drop

|

||||||||||||||||

| Flow rate [L/h] | [Note] XFS-1201 typical value |