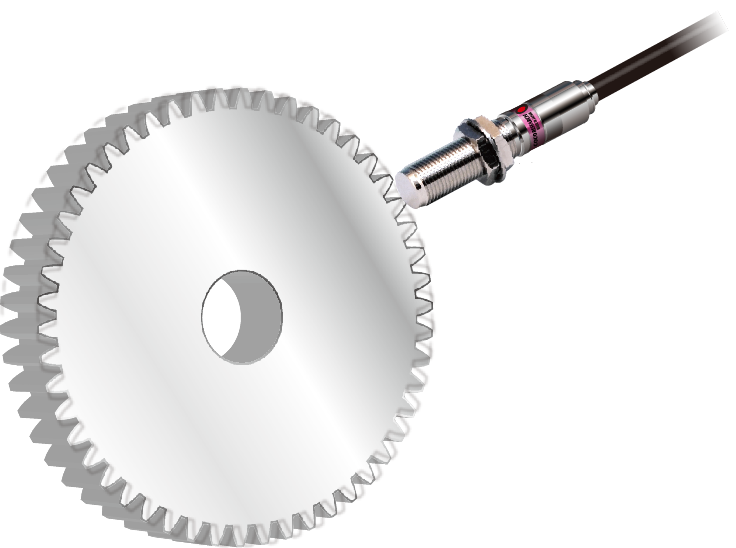

Composed of Hall elements, a magnet, and signal processing circuitry, it converts magnetic variations caused by rotation of a ferromagnetic detection gear into electrical signals for logic output.

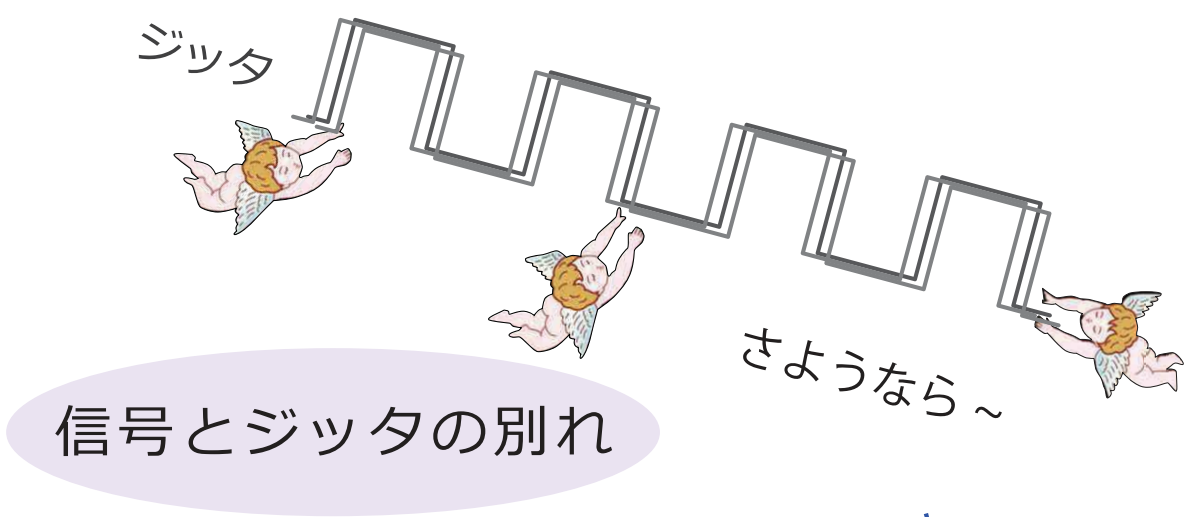

Capable of detection from 0 Hz, with jitter suppression technology enabling precise rotation measurement.

A line driver output type is available for stable operation even with long wiring distances.

Equipped with a reverse-connection protection circuit to prevent failures caused by wiring mistakes.

Accurate detection from start to stop of movement.

Stable detection even in high-temperature environments.

Contact us for models with extended temperature ranges.

- Line driver output

- Semi-open collector output

(open collector + pull-up)

- Differential (balanced) CMOS logic output

Can detect ferromagnetic gears of module m0.5 or larger, and ferromagnetic objects with uneven surfaces (1-2 teeth, holes, etc.).

| Models | IMG12-50S IMG16-50S IMG12-50S-J6M IMG16-50S-J6M [J6M: with connector]  |

IMG12-50LD IMG16-50LD IMG12-50LD-J6M IMG16-50LD-J6M [J6M: with connector]  |

IMG12-50D IMG16-50D IMG12-50D-J6M IMG16-50D-J6M [J6M: with connector]  |

| Output circuits | Semi-open collector (open collector + pull-up) |

Line driver (equivalent to AM26LS31) |

Differential (balanced) CMOS logic output (can be used as unbalanced signal) *1 |

| Pull-up Resistor | 800Ω | - | - |

| Detectable Object | Material: Ferromagnetic material such as S45C structural carbon steel (JIS G 4051) Standard gears and objects with steps of 3 mm or more |

||

| Detection Distance *2 | [m0.5] 0.1-0.3mm / [m1] 0.1-1.3mm / [m2] 0.1-2.7mm / [m2.5] 0.1-3.0mm [m means module] | ||

| Allowable Mounting Angle Tolerance | ±20° | ||

| Detection Element | 2-Hall-element differential method | ||

| Response Frequency | 0 - 20kHz | ||

| Output Voltage | Approximately 0.5 V lower than supply | H ≧ 2 V / L ≦ 0.8 V (no load) | Output at supply voltage |

| Output Current | ≦ 60 mA (sink current) |

Approx. 10 mA (with 100 Ω load) |

Supply 5 V: 0.72 mA Supply 15 V: 4.8 mA |

| Supply Voltage | 4.5 - 25VDC | 4.5 - 25VDC | 4.5 - 17VDC |

| Current Consumption | ≦ 0 mA (LED ON) |

≦ 20 mA (with 100 Ω load, LED ON) |

≦ 20 mA (LED ON) |

| Operating Temperature | -20 - +105℃ *3 | ||

| Magnet Polarity at Tip | South pole | ||

| Operation-check LED | Red LED | ||

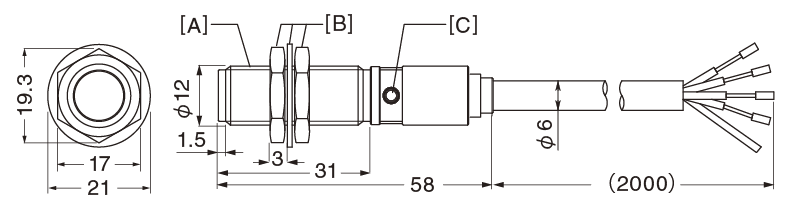

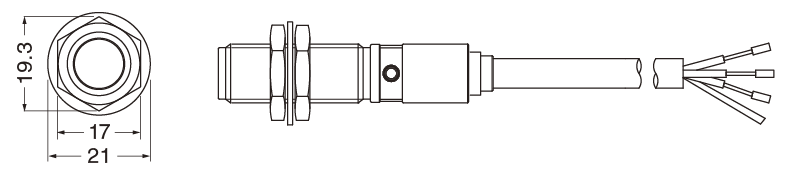

| Dimensions | [IMG12] M12(P=1thread)x L58 [IMG16] M16(P=1thread)x L58 |

||

| Case Material | Brass (nickel-plated) | ||

| Cable(PVC) | 2 m 3-core shielded cable conductor 0.2 sq |

2 m 2-pair (4-core) shielded cable conductor 0.2 sq |

|

| Insulation Resistance | ≧ 50 MΩ (between cable bundle and case at DC 500 V Megger) | ||

| Withstand Voltage | AC 500 V, 50/60 Hz, 1 min between cable bundle and case | ||

| Vibration / Shock Resistance | JIS E 4031:2013 (Railway vehicle products - vibration and shock test methods): Functional vibration test: X, Y, Z: 5.4 m/s2 rms, both directions per axis, 10 min each / Endurance vibration test: X, Y, Z: 30.6 m/s2 rms, 5 h per axis / Shock test: 300 m/s2, total 18 times (3 positive and 3 negative shocks per orthogonal axis) |

||

| Temperature Test | JIS C 60068-2-14:2011 | ||

| Mass *4 | [IMG12] Approx. 130 g [IMG12-***-J6M] Approx.150 g (cable: 50 g/m) [IMG16] Approx.160 g [IMG16-***-J6M] Approx. 180 g (cable: 65 g/m) |

||

| Accessories | 2 nuts, 1 serrated washer | ||

| Protection Rating | IP67 | ||

| RoHS | RoHS Compliance | ||

Brown: +V

White: SIG OUT 1

Black: SIG OUT 2

Blue: 0V

Shield: Insulated from main body

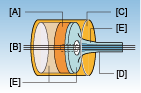

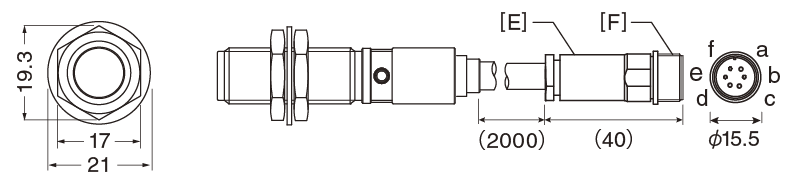

[A] M12 P=1 Thread

[B] Included Nut & Serrated Washer

[C] Operation-check LED / Alignment Mark

Brown: +V

Black: SIG OUT

Blue: 0V

Shield: Insulated from main body

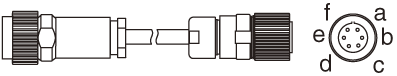

a: SIG OUT 1

b: SIG OUT 2**

c: +V

d: Shield

e: 0V

f: Empty (cannot be connected)

[E] R04-J6M Connector Round 6P (Male)*

[F] M14 P=1 Thread

*Connector by Tajimi Musen Denki Co., Ltd.

**IMG12-50S-J6M: empty>

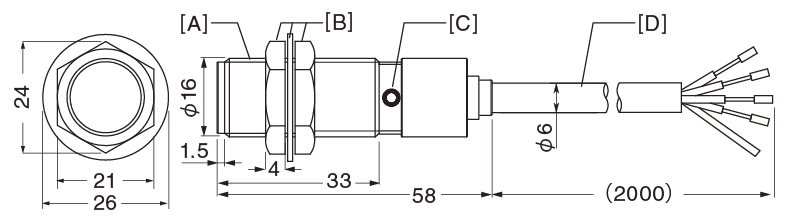

Brown: +V

White: SIG OUT 1

Black: SIG OUT 2

Blue: 0V

Shield: Insulated from main body

[A] M12 P=1 Thread

[B] Included Nut & Serrated Washer

[C] Operation-check LED / Alignment Mark

[D] Shielded Cable

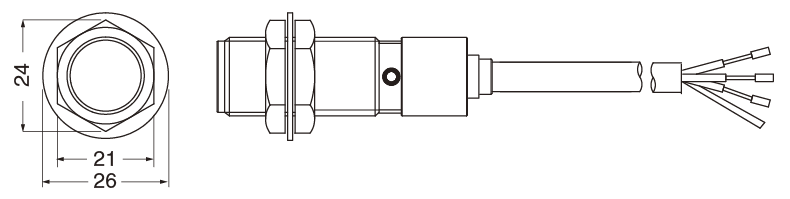

Brown: +V

Black: SIG OUT

Blue: 0V

Shield: Insulated from main body

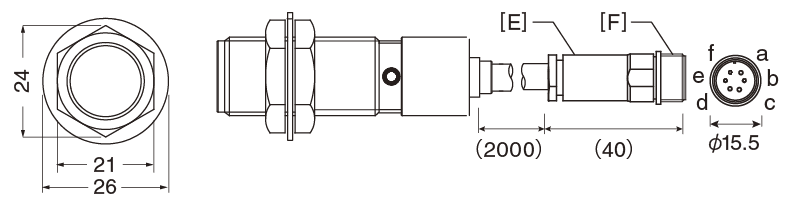

a: SIG OUT 1

b: SIG OUT 2**

c: +V

d: Shield

e: 0V

f: Empty (cannot be connected)

[E] R04-J6M Connector Round 6P (Male)*

[F] M14 P=1 Thread

*Connector by Tajimi Musen Denki Co., Ltd.

**IMG16-50S-J6M: empty

|

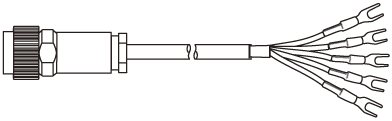

| Extension Cable Model | Cable End | ||

| Cable Length 5m | Cable Length 10m | Cable Length 20m | |

| DK-005 | DK-010 | DK-020 | Y-type Crimp Terminal |

|

White: SIG OUT 1 Black: SIG OUT 2** Brown: +V Blue: 0V Shield |

||

| R04-P6F* 6-Pin Female | Y-type Crimp Terminal 1.25Y-3 | ||

| DK-005T | DK-010T | DK-020T | Plug Connector |

|

a: SIG OUT 1 b: SIG OUT 2** c: +V d: Shield e: 0V f: Empty |

||

| R04-P6F* 6-Pin Female | R03-P6M* 6-Pin Male | ||