|

|

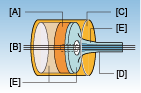

| Sensor Detection Surface | Conical PressTM |

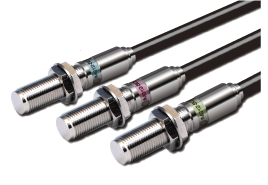

Prevents failures due to wiring errors, power supply reverse connection protection circuit [IMG]

Stable detection even in high temperature environments

|

Response 0 to 20kHz

Temperature -20 to +105°C

Power supply 4.5 to 25(17)V DC

Output circuit

Semi-open collector*1

Line driver

Differential (balanced) CMOS logic*2

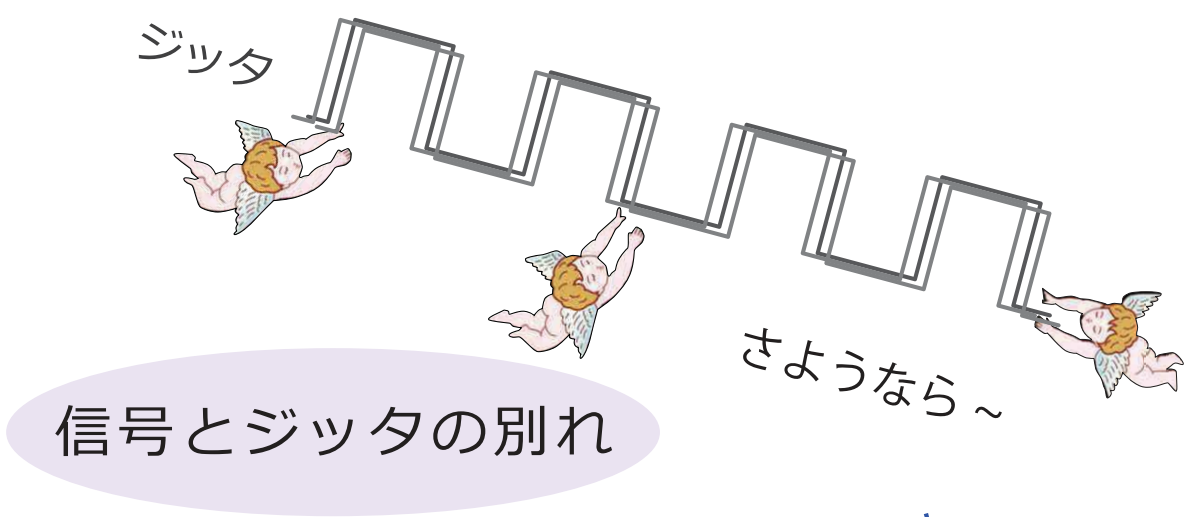

Detects from 0Hz and enables accurate rotation measurement with jitter suppression technology

Line driver output type can be used in environments with long wiring

Power supply reverse connection protection circuit prevents malfunction due to operational errors

|

Response 0 to 15kHz

Temperature -20 to +80°C

Power supply 4.5 to 25V DC

Output circuit

Semi-open collector*1

Pursues ease of use as a general-purpose sensor

Output circuit is unbalanced, providing an output voltage nearly equivalent to the sensor power supply voltage

Semi-open collector output circuit allows connection even when the pull-up voltage at the signal receiving end is higher than the sensor output.

|

Response 10 to 30kHz

Temperature -40 to +150°C

Power supply 5 to 12V DC

Output circuit

Open collector

Built-in amplifier, usable at high temperature (150°C)

|

Response 0 to 15kHz

Temperature

-40 to +140°C (RFP16A power less than 15V)

-40 to +126°C (RFP16A power supply above 15V)

-20 to +80°C (RFP16D)

Power supply 9 to 25V DC

Output circuit

Semi-open collector*1

(Phase A/B or speed/direction discrimination signal)

Detects both forward and reverse directions with a single cable. Reduces work such as hole drilling and mounting adjustment.

Compatible with *m1/1.5/2 Involute gears verified.

|

Response 220 to 50kHz

Temperature -20 to +100°C

No power supply required

Output circuit

Voltage output proportional to speed*3

0.5Vp-p min.

Self-powered by magnet and detection coil. No power supply required

Proximity to gear tooth tips, etc., and outputs a frequency signal proportional to the rotation speed

| For measuring rotational speed |

| List of speedometers |

| For measuring angles |

| List of counters and totalizers |

| Application examples list> |