| Input Pulse (frequency) output type sensors |

||

Gear sensor |

Flow sensor |

|

Rotary encoder |

Linear encoder |

|

Input Pulse ・5V logic ・Zero cross ・12V logic |

||

| Sensor power output ・12V/5V/others |

|

|

| Calculation [Speed, frequency, period, totalization] ・ PeriomaticTM B method ・Moving average ・Low cut ・Hold [Current/max./min./max. fluctuation range] ・Totalization [Zero shift, span shift, stop, start] |

||

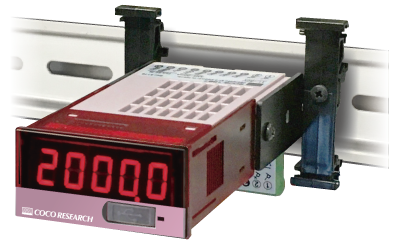

SPDL-24 series |

|

|

| Power supply ・7 to 30V DC ・USB power 5V |

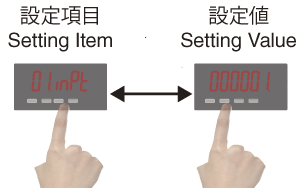

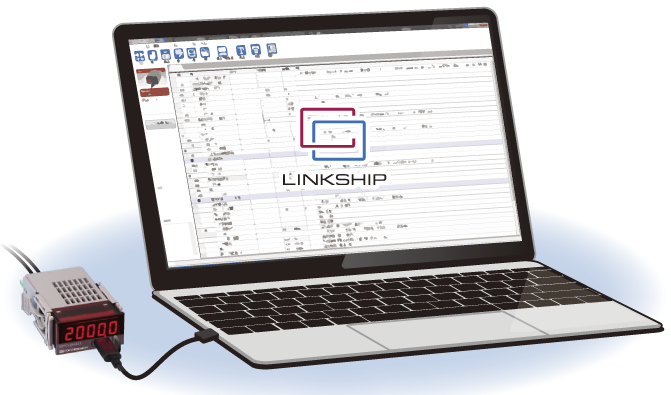

Setting ・LINKSHIP software ・Setting unit PL-5A |

|

| Output ・16bit analog ・Alarm ・CAN ・RS-485 ・Modbus ・USB |

||

PC |

PLC |

|

Logger |

Oscilloscope |

|

Indicator lamps |

||

| Angle |

| Position |

| Length |

| Flow rate |

| Rewind volume |

| >View more |

| See 1ms type> |

3-wire system greatly reduces wiring compared to BCD

Powerful error detection system for improved noise immunity and safety

| SAE J1939 (DLC 8 bytes or less) Customization Please contact us for other customizations. |

Resolution 50,000 or more/Full scale and zero scale settings, output zero adjustment

| 5V Logic |

| Zero cross |

| NPN open collector |

| 12V Logic |

| Customized signal |

| Input isolation |

| A/B phase input |

| Line driver input |

| Trigger Level 0-9.99V |

| Hysteresis select |

| Pull-up ON/OFF |

| 5V |

| 12V |

| Other voltage* |

| *Please contuct us |

Maximum 99

[Option] HOLD, zero shift, etc.

| SPDL-2401 |

| 17,600 yen and up* |

| Display only, Equipped with USB communication |

| SPDL-2451 |

| 19,300 yen and up* |

| DIN rail mounting, no display, Alarm output 2 points |

| See options and price list> |

| LINKSHIP Page > |

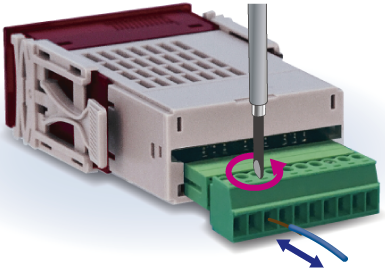

Detachable Plug Connectors

Simply connect the wires to the connector and plug it in by hand.

Detachable Plug Connectors

Spring lock type [Standard]

Detachable Plug Connectors

M2 screw type [Option]

Fixed Connector

Non-detachable [Customize]

Mounting hooks

Fixing the main body

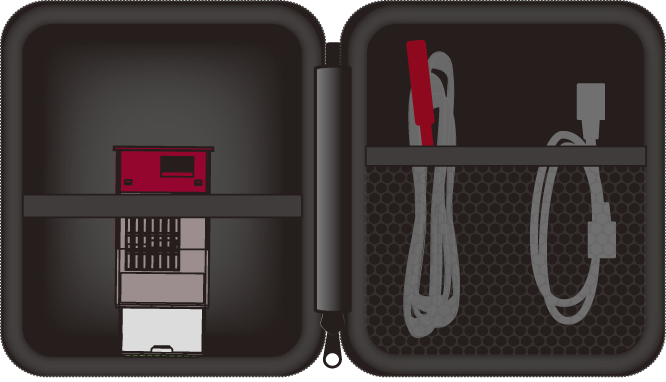

Carry PC, instrument, and cable, and measure with USB power supply. Storage case BXS-1 is also available.

|

>BXS-1 Overview |

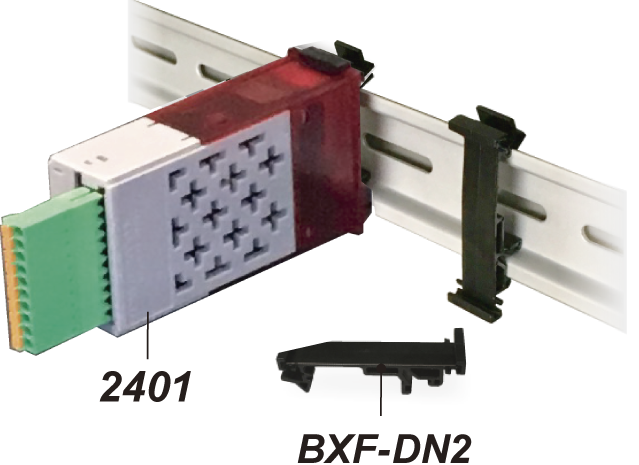

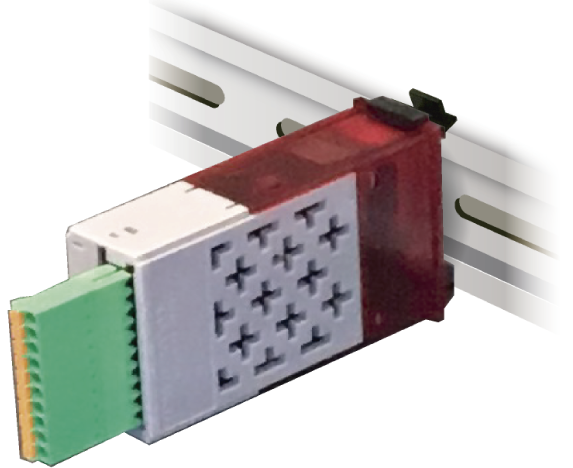

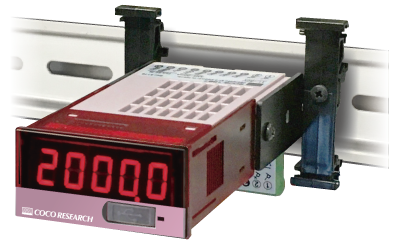

One-touch fixture and display-less type

|

|

|

| BXF-DN2 DIN rail attachment[sold separately] |

SPDL-2451 Display-less type |

SPDL-2431 With display type |

| >BXF-DN2 page |

| See more Applications > |

| Model List, Options and Prices > |

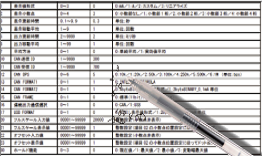

| Model | SPDL-2401 / SPDL-2411 / SPDL-2431 / SPDL-2451 | |||||||||||||||

| Measuring method | PeriomaticTM B method [Periodic arithmetic method] | |||||||||||||||

| Input | ||||||||||||||||

| Number of input points | 1 | |||||||||||||||

| Input frequency | 0.0006Hz to 1.0MHz | |||||||||||||||

| Input resolution | Approx. 10.4ns [96MHz] | |||||||||||||||

| Input Signal | 5V logic, zero cross, NPN open collector, 12V logic, input customized signal | |||||||||||||||

| Input method | Single-phase signal, 2-phase signal [direction signal, UP/DOWN signal] |

|||||||||||||||

| General-purpose input type | ||||||||||||||||

| Input Level and Sensitivity |

|

|||||||||||||||

| Input pulse | [Small] [Medium] 0.2 μs or more [Large] 0.3 μs or more, for both H and L levels | |||||||||||||||

| Input resistance | [5V logic] [zero cross] [NPN open collector] [Input customized signal, trigger level 4.7V or lower] 10kΩ [12V logic] [input customized signal, trigger level 4.71V or higher] 5kΩ |

|||||||||||||||

| Input withstand voltage | ±30V *Inputs and outputs are not insulated for the general-purpose input option. |

|||||||||||||||

| Line driver input Option | ||||||||||||||||

| Input signal | Line driver signal | |||||||||||||||

| Input withstand voltage | ±25V differential voltage | |||||||||||||||

| Recommended line driver | Equivalent to AM26LS31 | |||||||||||||||

| Termination resistance | 300Ω [standard specification] *Input and output are isolated for the line driver input option. |

|||||||||||||||

| 2-Phase[A/B] input Option Switchable between 1-phase and 2-phase [A/B] signals. When single-phase input is used, input level, Trigger level, etc. are the same as for 2-phase signals. | ||||||||||||||||

| Input Level and Sensitivity |

|

|||||||||||||||

| Input pulse | [Small/Medium] 0.2 μs or more, for both H and L levels | |||||||||||||||

| Input resistance | 10kΩ | |||||||||||||||

| Input withstand voltage | ±30V |

|||||||||||||||

| Common items for each input | ||||||||||||||||

| Input low-pass filter | Select from OFF, 500Hz, 5kHz, 120kHz, or 800kHz | |||||||||||||||

| Trigger edge | Fall | |||||||||||||||

| Input connector | Spring lock plug connector / [J04 option] M2 screw type plug connector | |||||||||||||||

| Sensor Power supply | [Option] [H] DC +12V±5% 60mA max / [L] DC +5V±5% 150mA max *When USB power is supplied, sensor power is not output. |

|||||||||||||||

| Calculation | ||||||||||||||||

| Measurement mode | Velocity meter/ Frequency meter/ Period meter [Seconds only] / Counter[Totalizer] | |||||||||||||||

| Calculation rate | Set the reference pulse number, reference change, and speed unit time with respect to the input frequency | |||||||||||||||

| Frequency divider ratio | 1 to 60000 | |||||||||||||||

| Output moving average | 1 to 99 | |||||||||||||||

| Dynamic PredictiveTM | 8 levels [including continuous and stop prediction] | |||||||||||||||

| Control input | None or 1 point [depending on model] [D2] Option to add 2 points. | |||||||||||||||

| [Setting contents] | Set a function for each control input and control from outside | |||||||||||||||

| Functions | Hold [current/max./min. value, max. fluctuation range], Zero/Span shift [count], Stop/Start count | |||||||||||||||

| ON logic | Normally open / Normally closed | |||||||||||||||

| [Operation Method] | ON when control input pin [ON logic] is shorted [open] to GND; setting is reflected when open [shorted] | |||||||||||||||

| [Data communication] | Command control is possible via communication [USB, CAN, RS-485] Commands set via communication cannot be released by terminal input. Reset execution is always required. |

|||||||||||||||

| Low cut | Low cut function Stop judgment at a speed lower than the set value |

|||||||||||||||

| Display | ||||||||||||||||

| Display Color | Red LED | |||||||||||||||

| Indicator [Numerical Display] | 5-digit, 7-segment LED Character height 9mm / Display range:-19999 to 99999 Polarity indication: Reverse rotation -Lighted / Over indication: OL / Zero indication: Leading zero suppress |

|||||||||||||||

| Decimal point position | Semi-fixed Decimal point position is set in program mode. [0] *****, [1] ****.* to [4] *.**** | |||||||||||||||

| Display update time | 0.3 sec [settable from 0.1 to 9.9 sec] | |||||||||||||||

| Display accuracy | 20ppm ± 1 digit | |||||||||||||||

| Indicator [3 round LEDs] | LED 1 point [selected from power/ control input/ trigger/ comparator output] |

|||||||||||||||

| USB communication | ||||||||||||||||

| Communication specification | USB2.0 [Serial port communication by USB virtual COM 230.4kbps] | |||||||||||||||

| Communication function | Writing/reading of set values/ Continuous output of measured values | |||||||||||||||

| Output update time | 40 to 9999.9ms, settable in 0.1ms increments |

|||||||||||||||

| General Information | ||||||||||||||||

| Operating temp./humidity | -10°C to +50°C / 35 to 85%RH [non-condensing] | |||||||||||||||

| Power supply voltage | 7 to 30V DC with reverse connection protection. Power supply from USB host: 5V | |||||||||||||||

| Power consumption | 3W or less | |||||||||||||||

| Isolation | Power Supply/ Other Input/Output | |||||||||||||||

| Withstand voltage | Power supply/ Other input/output: 500V DC between each terminal for 1 minute | |||||||||||||||

| Weight | Approx. 60g |

|||||||||||||||

| CAN Option | ||||||||||||||||

| Communication specifications | CAN2.0B 10 k / 20 k / 50 k / 100 k / 250 k / 500 k / 1M bps [Format] INTEL/MOTOROLA, [Frame] 11bit/29bit | |||||||||||||||

| Communication function | Writing/reading of set values/ Continuous output of measured values | |||||||||||||||

| Setting item | CAN transmit ID, CAN receive ID | |||||||||||||||

| Output update time | 40ms to 9999.9ms settable in 0.1 ms increment |

|||||||||||||||

| RS-485 communication option Modbus RTU support is available upon request. | ||||||||||||||||

| Number of connected units | 32 units [max.] | |||||||||||||||

| Communication format | 2-wire multi-drop serial communication | |||||||||||||||

| Communication method | Asynchronous | |||||||||||||||

| Communication standard | RS-485 | |||||||||||||||

| Communication speed | 9600bps / 19200bps / 38400bps Set in program mode | |||||||||||||||

| Data format | Start bit: 1 bit / Stop bit: 1 bit / Data length: 8 bits / Parity bit: None | |||||||||||||||

| Communication code | ASCII | |||||||||||||||

| Communication function | Writing/reading set values/measurement value output [response to request command] |

|||||||||||||||

| Analog output option | ||||||||||||||||

| Output signals | [E1] 0 - 10V [E5] 0 - 5V [R1] ±10V [R5] ±5V [I1] 4 - 20mA [Select a model] | |||||||||||||||

| D/A conversion method | DAC conversion method | |||||||||||||||

| Output resolution | 16bit16bit [50,000 or more] | |||||||||||||||

| Load resistance | [Voltage output] 4.7kΩ or more / [Current output] 300Ω or less | |||||||||||||||

| Output accuracy | [Voltage output] ±0.1% of FS @ 23℃/ [Current output] ±0.1% of FS @ 23℃ | |||||||||||||||

| Temperature fluctuation | ±200ppm/℃ or less | |||||||||||||||

| Output scaling | Arbitrary scaling is possible by full scale and zero scale settings | |||||||||||||||

| Output update time | 40 to 9999.9ms settable in 0.1ms increments | |||||||||||||||

| Input/output delay time | Output update time + analog rise time 150 μs max. |

|||||||||||||||

| Alarm [Comparator] output option | ||||||||||||||||

| Setting method | Set in program mode | |||||||||||||||

| Number of outputs | 2 points (or 1 point) depends on the models 1 point for line driver input and analog output with comparator output specification. | |||||||||||||||

| Output form | Isolated non-contact output [photo-MOS relay] No polarity. When comparator operating condition is ON, resistance between COMP and COM 50 Ω or less for C2 option [2 comparator] / 100 Ω or less for C1 option [1 comparator] |

|||||||||||||||

| Output load voltage | Peak AC/DC280V 100mA [resistive load] / ON resistance 50Ω or less | |||||||||||||||

| Output logic | Comparison is made with polarity [0 is greater than minus]

|

|||||||||||||||

| Update time | Depends on analog output update time setting. Response time 1ms [max.] | |||||||||||||||

| View more > |

| Load cell/Pressure/Strain | CAN to analog |

| DC current | DC voltage |

| Thermocouple meter | Thermistor meter |

| RTD meter | Resistance Meter |

| Speed/Count, Pulse Freq. | Torque/Freq.deviation |

Various Outputs

Software LINKSHIP

For data logging, setting

Customization