Applications >HOME >Application list >Japanese Page

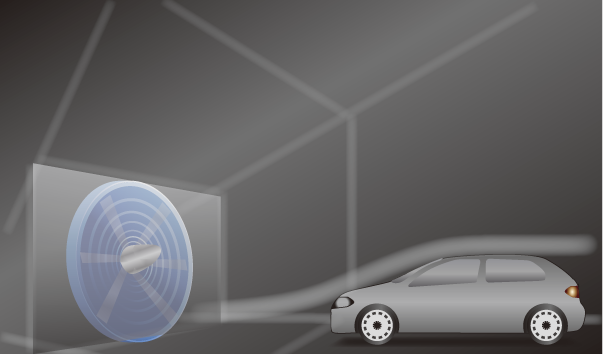

Wind Tunnel Testing / vehicles, motorcycles, architectural and civil engineering structures, etc.

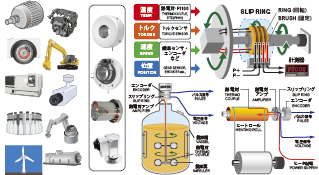

In addition to measuring wind velocity, it also measures rotational speed, temperature, current, voltage, resistance, and torque. It is also used for wind tunnel testing of snow accumulation, fire smoke, thermal stratification, etc. |

|

Overview

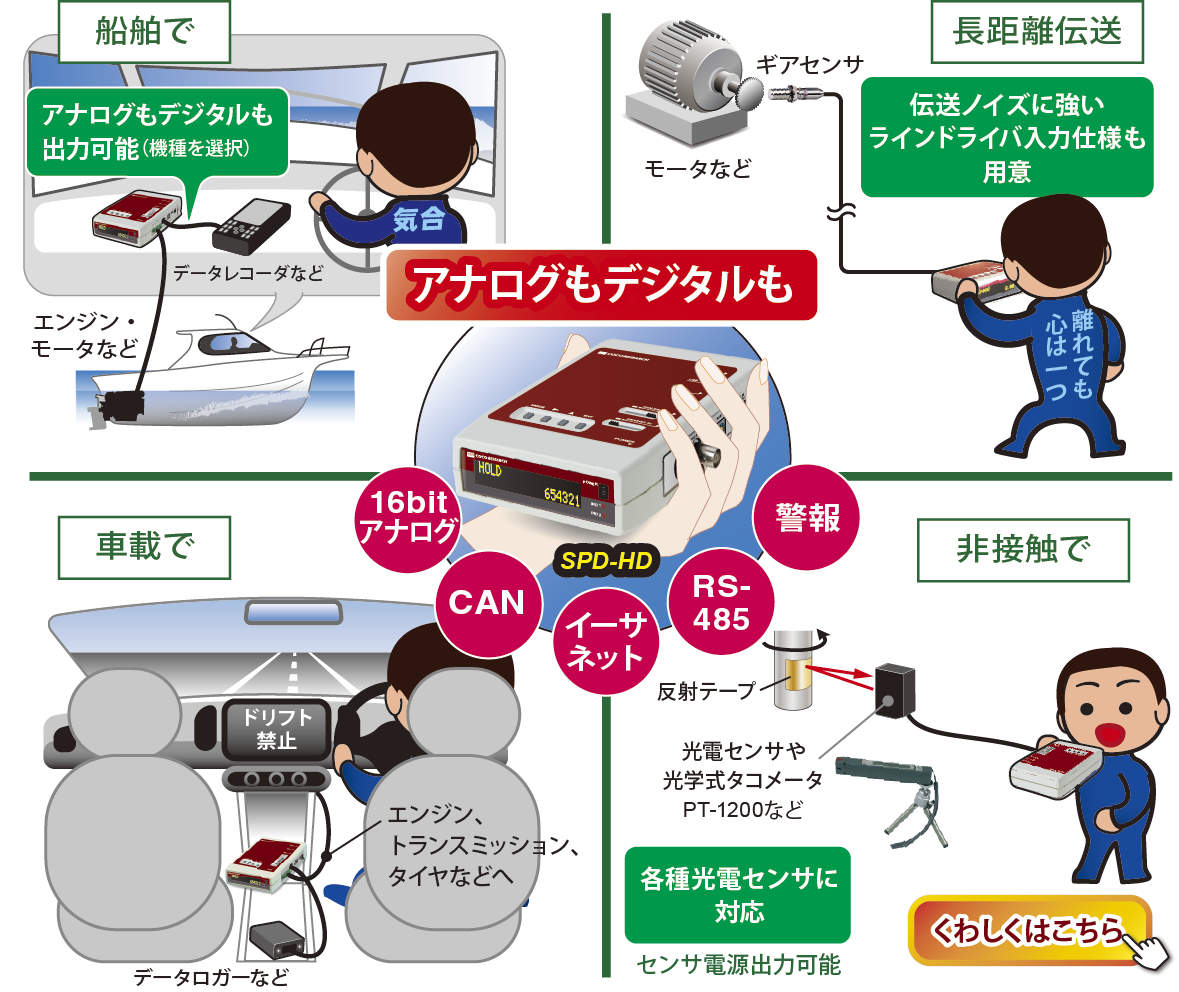

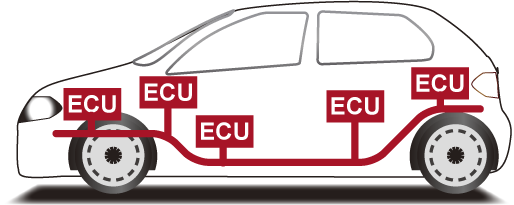

Frequency pulse signals from an anemometer are input to a speedometer, converted to analog signals or CAN, and output to a logger or PC.

At the same time, it collects data on vehicles, building and civil engineering structures, etc.,

with measuring instruments for rotational speed, temperature, current, voltage, resistance, torque, etc.

Blower |

→ → → → → → → → |

Anemometer |

→ → → → → → → → |

|

|

|||||||||||||||||||||

| ↓ ↓ Pulse signal |

→ |

|

In this case study, what we can do

Measuring instruments and signal converters

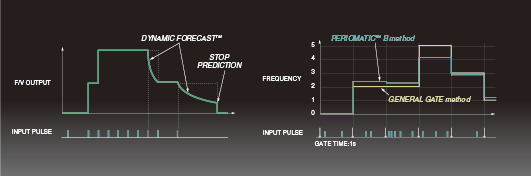

- High accuracy from very low to high speeds with our unique Periomatic™. - Various measurements such as speed, temperature, current input, voltage input, - Analog output selectable from 0-10V, 0-5V, ±10V, ±5V, and 4-20mA (optional, specified when ordering). - An alarm signal can be output when the specified rotation speed is exceeded. (Option) - Measurement data can be output via CAN. (Option) - Converts CAN data from vehicles and other devices to analog signals. - Customization is possible to combine multiple speed, position, angle, temperature, current, voltage, |

Selection Points

Measuring instruments and signal converters

- Unique Periomatic™ calculation (speedometer)

- Various product variations such as rotational speed, temperature, current, voltage, resistance, torque, CAN, etc.

- Fastest update time, analog output

- Fastest update time of 1 ms, CAN output

- CAN analog converter for easy confirmation of specific CAN data in a vehicle

- Customized support for multi-CH, boxed, and mixed loading of different measurement types

- Supports line driver input (speedometer/torque meter), which is resistant to noise during long-distance transmission.

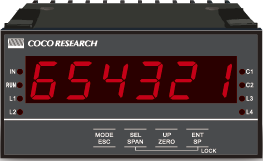

EX series: Signal converters / Panel meters

| Series Name | EX48 [48x96 size] | EX24 [24x48 size] | EXL24 [24x48 size] | ||||

|

|

|

Common Features

USB RS-485 Modbus CAN |

||||

| Thermistor meter | Under Development |

|

|

High conversion accuracy with unique calculation method | |||

| RTD meter |

|

|

|

Combines with Pt100 to measure temperature | |||

| Thermocouple meter |

|

|

|

Compatible with TC types K. J, R, E, T, B. N, S | |||

| DC Ammeter |

|

|

|

±10A to ±100μA: Shunt resistance of 40mΩ or less (±5A, ±2A type) for low loss. | |||

| DC Voltmeter |

|

|

|

±70V to ±10mV: For real-time measurement and feedback control. | |||

| Resistance Meter |

|

|

|

4 ranges (150Ω/1.5kΩ/10kΩ/40kΩ) switchable by setting. | |||

| Speed (frequency) meter |

|

|

|

PERIOMATIC™ calculation for High accuracy and High speed response | |||

| Torque (Freq.deviation) meter |

|

|

|

For torque or flex fuel sensors with deviation frequency signal output | |||

| Output Update Time* | 0.1ms/1ms/2ms- | 0.1ms/1ms/2ms- | 40ms- | *Varies depending on model |

| Customization:We support from one unit. | Customization page > |

| Boxed - Calibration is possible as an embedded product. - Calibration documents and traceability charts can be issued. |

Function change - Input, output, calculation, etc. - Changing the input power supply or sensor power supply output - Adding arithmetic formulas - Adapting output voltage values, communication specifications, etc. |

|

Please consult with us about your desired boxed or rack assembly.

|

Related Applications