Application >HOME >Application list >Japanese Page

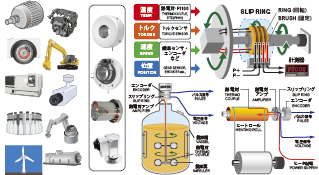

Operation check, fault diagnosis, and testing of ships with pulse generator

Inspections using a pulse generator are used to simulate signal input for marine remote control systems and other systems,

and to check the operation of engines, motors, propellers, and other equipment.

Since operation checks and troubleshooting can be easily performed, it is effective for periodic maintenance and diagnosis of abnormalities.

Overview

Pseudo-signals from the pulse generator are input to remote control systems, engines, motors, etc., to check operation.

Data can be collected with various sensors and measuring instruments for speed, temperature, current, voltage, resistance, torque, etc.

Pulse Generator QP-3X

|

→→→ DummyPseudo Signal Pulse |

Remote control systems, engines, motors, etc. for ships

|

|

|||||||||||||||||||||

|

||||||||||||||||||||||||

For also automobiles, motorcycles, construction machinery, agricultural machinery, factory equipment, etc.

What this case can do

Pulse Generator

Checking engines and motors

Using a pulse generator, dummy signals are input to the remote control.

Reproduce the position of the operation lever and throttle, and check if the engine, motor, control unit, etc. respond properly.

Check the operation of screws, etc.

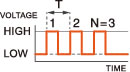

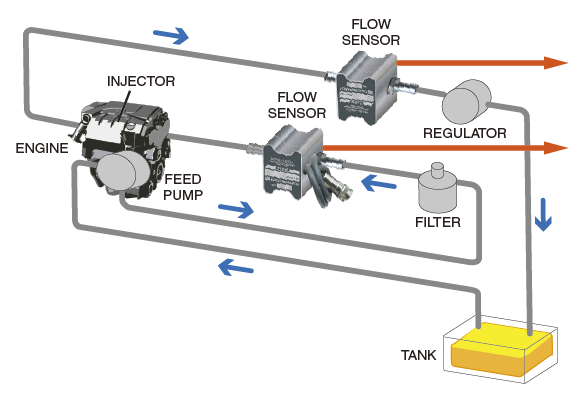

Checks whether the throttle opening and propeller pitch of a marine engine are accurately reflected by giving pulse signals.

No need to start the engine. Check forward/reverse rotation of the screw using the A/B phase signal of the pulse generator as a dummy signal.

Abnormality Diagnosis and Troubleshooting

When a remote control system malfunction occurs, pseudo-signals are input to identify at which stage the error occurs.

Analysis of communication breakdown, signal delay, and malfunction factors.

Endurance test/stress test

Repeated pulse input is performed to test reliability and durability in long-term use.

Varying specific frequencies to check for abnormal operation and effects of aging.

Measuring instruments and signal converters

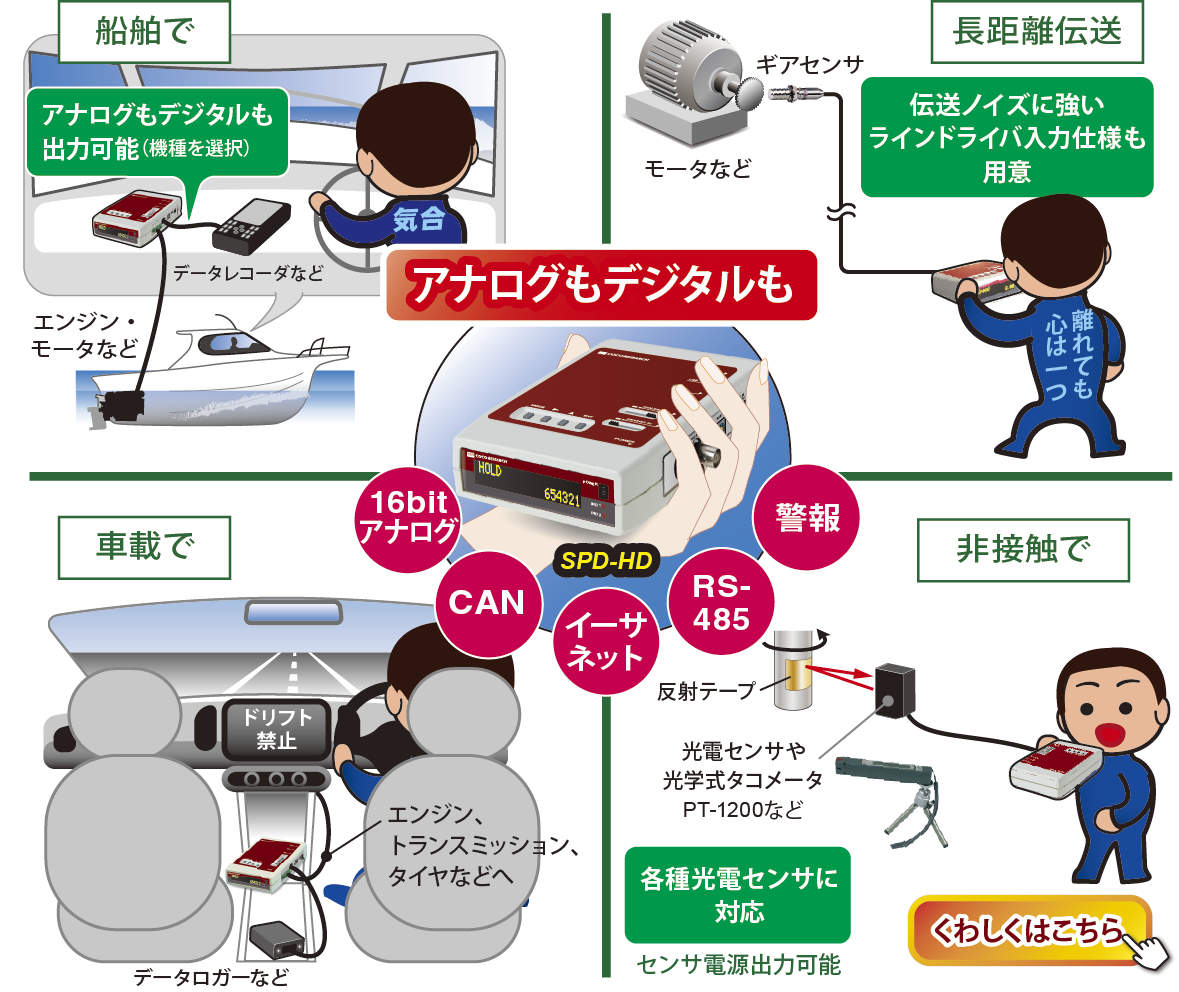

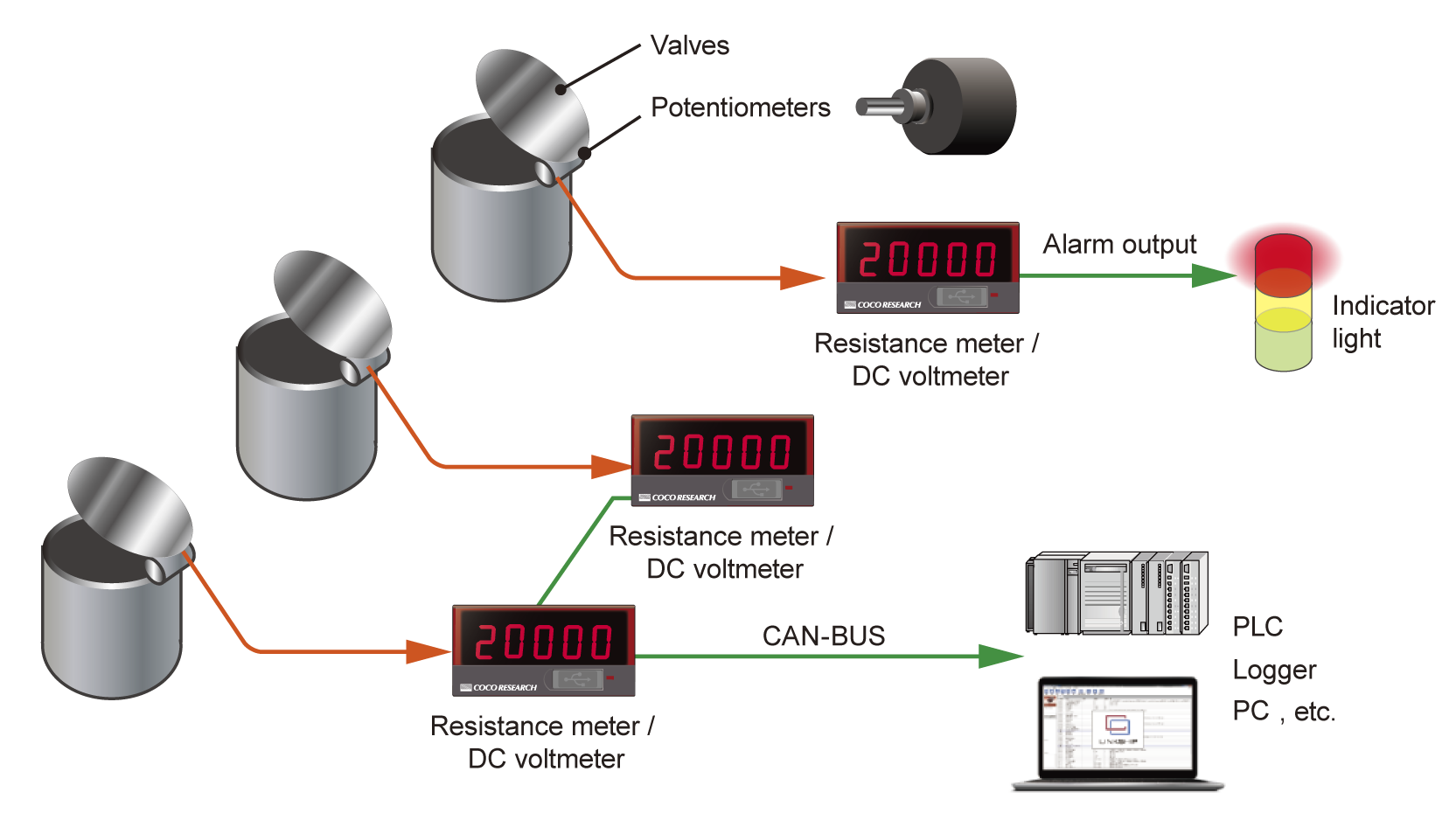

- Analog output selectable from 0-10V, 0-5V, ±10V, ±5V, 4-20mA (optional, specified when ordering).

Output update is as fast as 0.1 ms (speedometer). Full scale value can also be set.

- Alarm (warning) signal can be output when the specified rotation speed is exceeded. (Option)

- CAN output of measurement data. (Option)

- Customization, to combine multiple speed, position, angle, temperature, current, voltage, resistance, torque, etc. into one unit.

Power supply, connectors, wiring, etc. can be combined for ease of use.

Selection Points

Pulse Generator

- Oscillator, N-pulse, sweep, and other oscillation modes that can be used for dummy signals for various inspections and tests

- Signal output: Variable voltage, semi-open collector, 90° phase difference A/B phase

- 2-way power supply: 4 AA alkaline batteries or included AC adapter

- Retractable BNC connector (locking pop-up type) for easy portability

- LCD with backlight for easy viewing in dark environments

Measuring instrumentation and signal converter

- Unique Periomatic™ calculation (speedometer). Handheld type SPD-HD also available

- Various product variations including rotational speed, temperature, current, voltage, resistance, torque, CAN, etc.

- Fastest update time, analog output

- CAN output: Fastest 1ms update

- Customizable for multi-CH, boxed, and mixed measurement types

- Supports line driver input (speedometer/torque meter), resistant to noise during long-distance transmission

| Products | Points | Overview | |

|---|---|---|---|

|

Universal Pulse Generator QP-3X Product Page |

|

- Various oscillation: Oscillator, N-pulse, sweep Dummy signal for various inspections and tests |

|

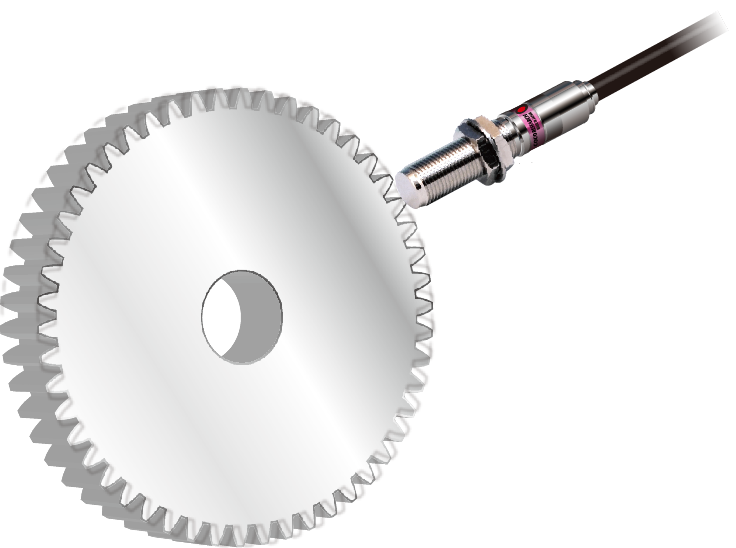

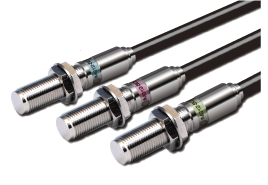

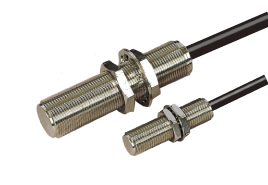

Magnetic Gear speed Sensor IMG Series Product Page |

Semi-open collector output Differential (balanced) CMOS logic output Line driver output Wide power supply range Conical press™ |

- Detectable from 0Hz. Suppresses jitter for more accurate rotation measurement. - Model selection by output type - Semi-open collector (open collector + pull-up) output - Differential (balanced) CMOS logic output - Line driver output - Sensor sensing surface: Fully sealed one-piece metal case with IP67 rating - Cable pullout: Unique Conical Press™ for water- and oil-contaminated environments |

|

Magnetic Gear speed Sensor FDP Series Product Page |

Semi-open collector output Wide power supply range Conical press™ |

- Fully threaded housing for high degree of freedom of mounting |

|

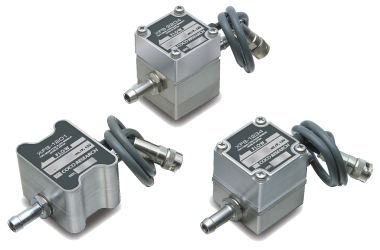

Capacity Type Volumetric Flow Sensor XFS Series Product Page |

|

- Low pressure loss due to special elliptical gears |

|

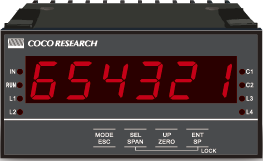

Pocketable Speed/Totalizer [Switchable] SPD-HD Product Page |

RS-485 Modbus CAN Analog output Alarm output Zero shift Span shift Totalizer stop/start LINKSHIP software |

- Speed/totalizer [switchable type] for speed meter, frequency meter, tachometer, flowmeter, totalizer, etc. |

EX series: Signal converters / Panel meters [ CAN, 16bit Analog output ]

| Series Name | EX48 [48x96 size] | EX24 [24x48 size] | EXL24 [24x48 size] | ||||

|

|

|

Common Features

USB RS-485 Modbus CAN |

||||

| Thermistor meter | Under Development |

|

|

High conversion accuracy with unique calculation method | |||

| RTD meter |

|

|

|

Combines with Pt100 to measure temperature | |||

| Thermocouple meter |

|

|

|

Compatible with TC types K. J, R, E, T, B. N, S | |||

| DC Ammeter |

|

|

|

±10A to ±100μA: Shunt resistance of 40mΩ or less (±5A, ±2A type) for low loss. | |||

| DC Voltmeter |

|

|

|

±70V to ±10mV: For real-time measurement and feedback control. | |||

| Resistance Meter |

|

|

|

4 ranges (150Ω/1.5kΩ/10kΩ/40kΩ) switchable by setting. | |||

| Speed (frequency) meter |

|

|

|

PERIOMATIC™ calculation for High accuracy and High speed response | |||

| Torque (Freq.deviation) meter |

|

|

|

For torque or flex fuel sensors with deviation frequency signal output | |||

| Output Update Time* | 0.1ms/1ms/2ms- | 0.1ms/1ms/2ms- | 40ms- | *Varies depending on model |

| Customization:We support from one unit. | Customization page > |

| Boxed - Calibration is possible as an embedded product. - Calibration documents and traceability charts can be issued. |

Function change - Input, output, calculation, etc. - Changing the input power supply or sensor power supply output - Adding arithmetic formulas - Adapting output voltage values, communication specifications, etc. |

|

Please consult with us about your desired boxed or rack assembly.

|